Bio-CNG (CBG)

Product

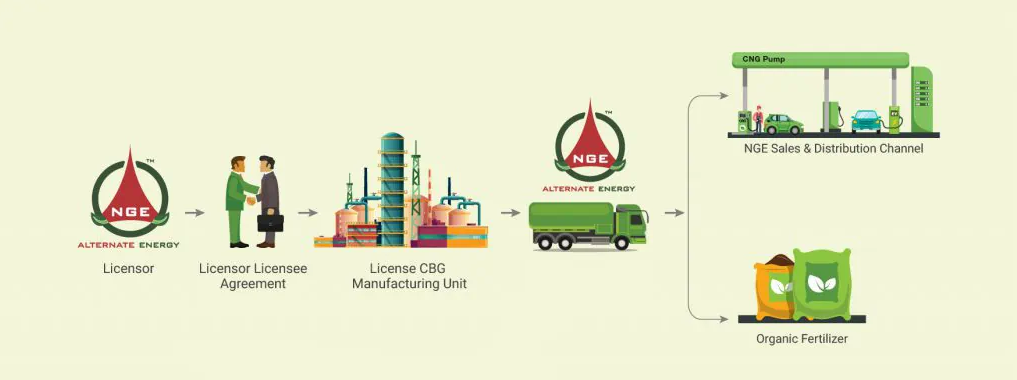

Production Project

Retail Outlet

Biogas Manufacturing Plant

A naturally produced gas through the anaerobic decomposition of biomass like agricultural waste, animal droppings, residue from agro-food industries, domestic waste, etc. As we all know Bio-CNG is purified The main constituents are methane, carbon dioxide, and traces of gases like water vapour, oxygen, hydrocarbons, ammonia, etc. It is a highly combustible gaseous fuel that releases heat and energy. The constituents like water vapour, hydrogen sulphide, and carbon dioxide make biogas very unsuitable to be utilized as fuel. Biogas is purified to remove hydrogen sulphide, carbon dioxide and water vapour and thereafter compressed as Compressed Bio Gas.

Biogas to Bio-CNG Process

Bio-CNG is the purified and compressed form of biogas with more than 90% of methane content. The purification of biogas is essential to increase its energy potential. It is clean renewable fuel with calorific value and other properties similar to CNG. Hence Bio-CNG(CBG) can replace CNG in industries, automobiles, and domestic & commercial use.

Properties of Bio-CNG

In comparison of both, which has a methane content of 92–98% and a carbon dioxide content of 35–45%, biogas has a methane content of 55–65% and a carbon dioxide content of 2–8%. Bio-CNG has roughly 52,000 kilojoules (kJ) per kg or about 167 per cent more calories per weight than biogas. Due to its high methane content, calorific value, low moisture, hydrogen sulphide, and impurity content, bio-CNG is the finest fuel for vehicles and power plants. Additionally, due to its low emission levels, It is a more environmentally friendly fuel than biogas.

What is required to produce Bio-CNG?

It is produced through the decomposition of biogenic waste in the absence of oxygen. Biogenic waste is a broad term used for waste generated by plants and animals. The biomass is cleaned/scrubbed to get the desired quality of Biogas.

The following are the substrate of Bio-CNG generation:

Animal waste.

Sources of animal waste:

- Dairy Farms

- Poultry Farms

- Other Animal Husbandry

- Plant waste/ Farm Waste

Sources of plant/ farm waste:

- Paddy Straw

- Fodder Crop

- Napier Grass

- Solid Organic Waste

- Municipal Solid Waste

Difference between CNG & Bio-CNG

The chemical properties of Bio-CNG are similar to CNG, both are compressed methane and have the same calorific value. Contrary to compressed natural gas (CNG), which is a by- product of the petroleum industry, compressed biogas can be made from any biomass, including crop residue, animal manure, sugarcane press mud, municipal wet waste, and wastewater from sewage treatment facilities.

* Terms and Condition Apply

NOTE – “As Per CBG BIS Standard”