Welcome to Nexgen Energia, your partner in sustainable energy solutions! We are a leading EPC (Engineering, Procurement, and Construction) company specializing in setting up CBG (BIO-CNG) manufacturing plants across India. With our cutting-edge technology and comprehensive assistance, we are committed to helping entrepreneurs establish their own CBG (BIO-CNG) manufacturing plants, contributing to India's green energy revolution.

At Nexgen Energia, we understand the urgent need for sustainable and renewable energy sources in today's world. CBG, also known as BIO-CNG, is a promising green fuel that is produced from organic waste, such as agricultural residues, food waste, and animal manure, through a process called biomethanation. It is a clean, renewable, and carbon-neutral fuel that can be used for various applications, including transportation, cooking, and electricity generation. CBG not only reduces greenhouse gas emissions and air pollution but also promotes circular economy and waste management.

Our team of experienced professionals at Nexgen Energia provides end-to-end solutions for setting up CBG (BIO-CNG) manufacturing plants. From project conceptualization and feasibility studies to design, engineering, procurement, construction, and commissioning, we offer comprehensive services to ensure a smooth and successful project execution. We utilize state-of-the-art technology and adhere to international standards in our EPC projects, ensuring high-quality and efficient CBG production.

We are inviting entrepreneurs across India to partner with us in setting up CBG (BIO-CNG) manufacturing plants at their locations. As a partner, you will benefit from our expertise, technical know-how, and industry insights, as well as our strong network of suppliers, contractors, and regulatory authorities. We provide customized solutions tailored to your specific requirements and ensure compliance with all relevant regulations and guidelines

By partnering with Nexgen Energia, you will not only contribute to India's green energy goals but also tap into the growing market demand for sustainable and renewable fuels. CBG has immense potential in India, given the abundant availability of organic waste and the government's focus on promoting green energy. It presents a lucrative business opportunity for entrepreneurs who are passionate about sustainability and want to make a positive impact on the environment and society

Join us in our mission to create a greener and more sustainable future for India. Contact us today to explore how we can assist you in setting up a CBG (BIO-CNG) manufacturing plant at your location. Let's work together towards a cleaner and brighter tomorrow!

What is a Compressed Biogas Plant?

A Compressed Biogas Plant, also known as CBG Plant, is a facility that produces clean and renewable energy from organic waste. The process involves converting biodegradable waste, such as food and agricultural waste, animal manure, and sewage, into biogas through a process called anaerobic digestion. The biogas produced is then compressed and purified to remove impurities, resulting in a high-quality fuel known as Compressed Biogas (CBG).

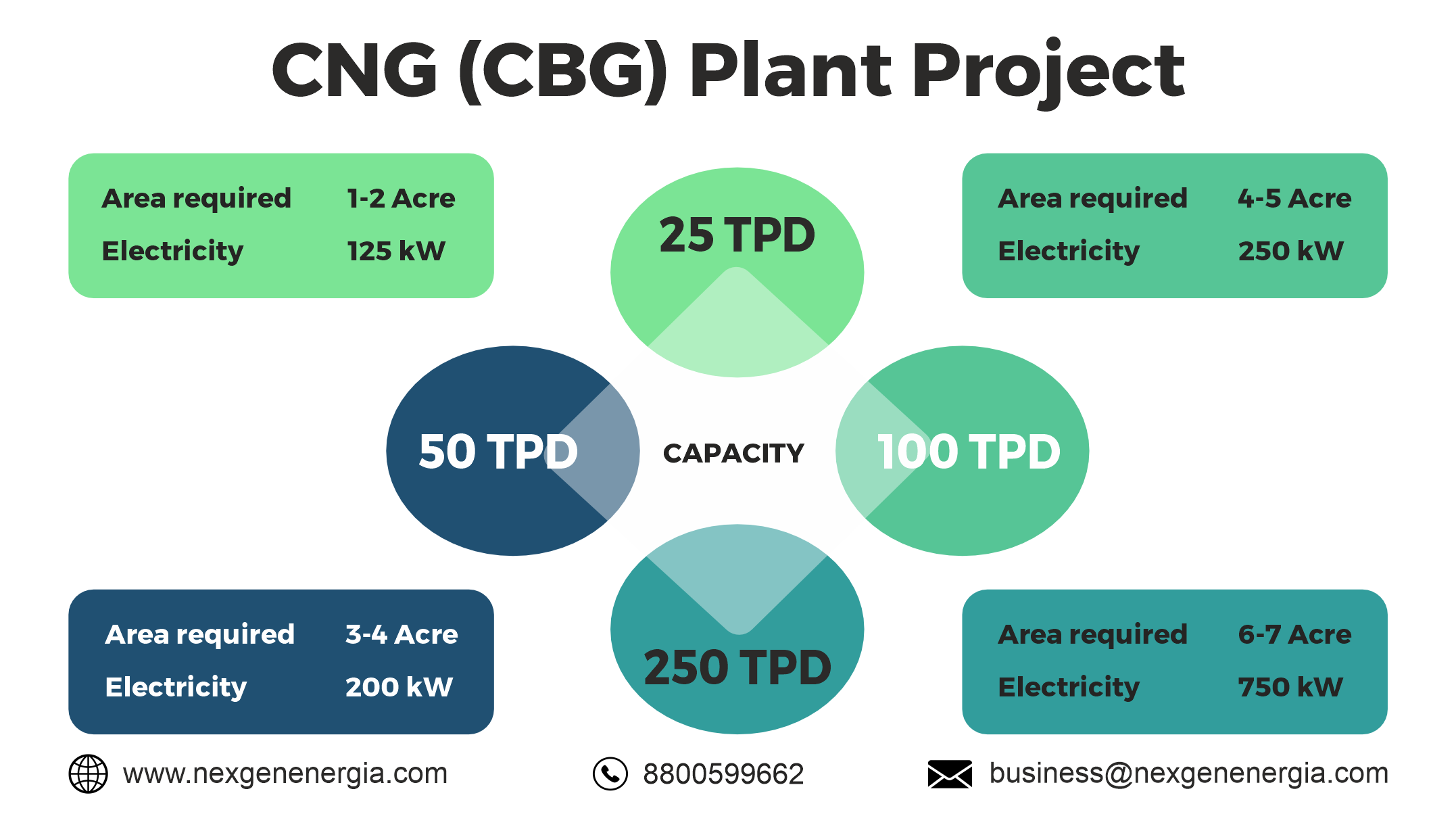

CBG Plants can be set up at different scales, depending on the availability of feedstock and the energy demand. Small-scale plants can be set up at farms, households, or small communities, while large-scale plants can be set up at industrial or municipal sites. CBG Plants can also be integrated with existing waste management systems, such as landfill sites, to capture and utilize the biogas generated.

CBG is a versatile fuel that can be used for various applications, such as cooking, heating, transportation, and power generation. It is a clean and sustainable alternative to fossil fuels and can significantly reduce carbon emissions, air pollution, and dependency on imported fuels. CBG also has a high energy density and can be stored and transported easily in compressed form.

CBG manufacturing plants are specifically designed to produce compressed biogas (CBG) by compressing the biogas to reduce its volume and increase its energy density. CBG production plants typically include a biogas upgrading system, which removes impurities such as carbon dioxide and moisture from the biogas to produce a purer form of methane. The resulting CBG can be used as a substitute for natural gas in vehicles, industrial processes, and other applications.

Setting up a CBG Plant can bring multiple benefits, such as generating revenue from waste, reducing waste disposal costs, creating jobs, and contributing to sustainable development. The technology is mature and proven, and the market for CBG is growing rapidly, creating opportunities for entrepreneurs and investors.

Biogas plants and CBG production plants are important components of the circular economy, as they allow waste materials to be recycled and repurposed as a valuable resource. By diverting organic waste from landfills and incineration facilities, biogas plants and CBG production plants can help reduce greenhouse gas emissions and contribute to a more sustainable future.

If you're interested in investing in a biogas plant or CBG production plant, there are a few key considerations to keep in mind. First, it's important to choose a site that is easily accessible to sources of organic waste, such as agricultural or food processing facilities. Second, you'll need to invest in equipment and infrastructure to collect, transport, and process the waste materials. Finally, it's important to have a reliable market for your CBG, such as a local bio company or other potential customers.

WE CREATE A SUSTAINABLE, EFFICIENT AND ECONOMIC SOLUTION

What are the Five areas of Compressed Biogas Plants ?

A biogas plant has five major areas that make the biogas production process possible

- Reception area (Feeding)

- Digester Area (fermentation tank/CSTR)

- Purification Area (PSA)

- Filling Area (Compression & Cascading)

- Bio Fertiliser Organisation Area (Slurry Tank & Packaging)

The Digester Area: A waterproof airtight container with a means of entry for biomass, the digester contains all the waste to be transformed into energy. Then, to shift the biomass periodically to enable the gases and prevent the formation of layers, agitators come into action. After the fermentation, a digester via pipe enables the digest to be removed.

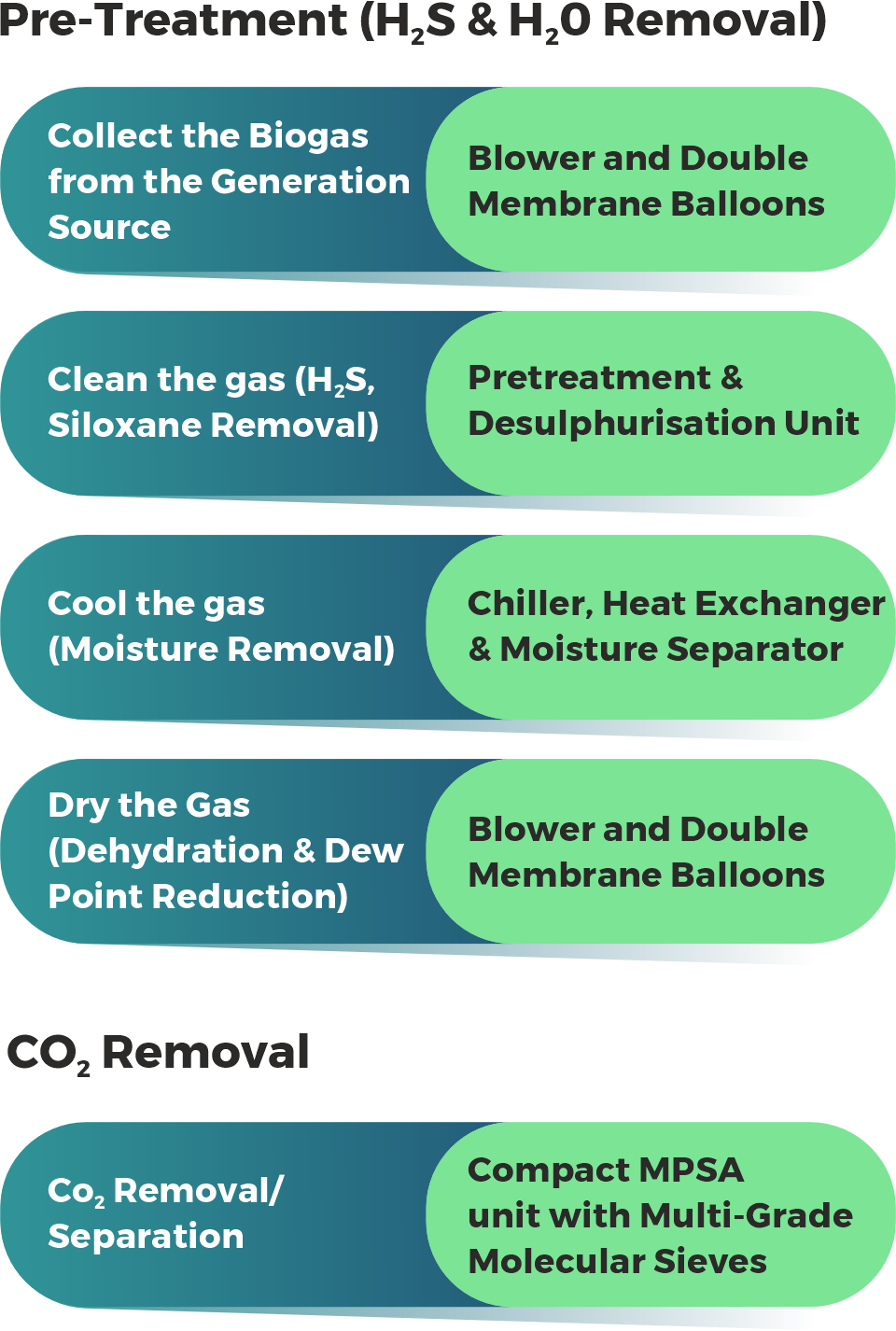

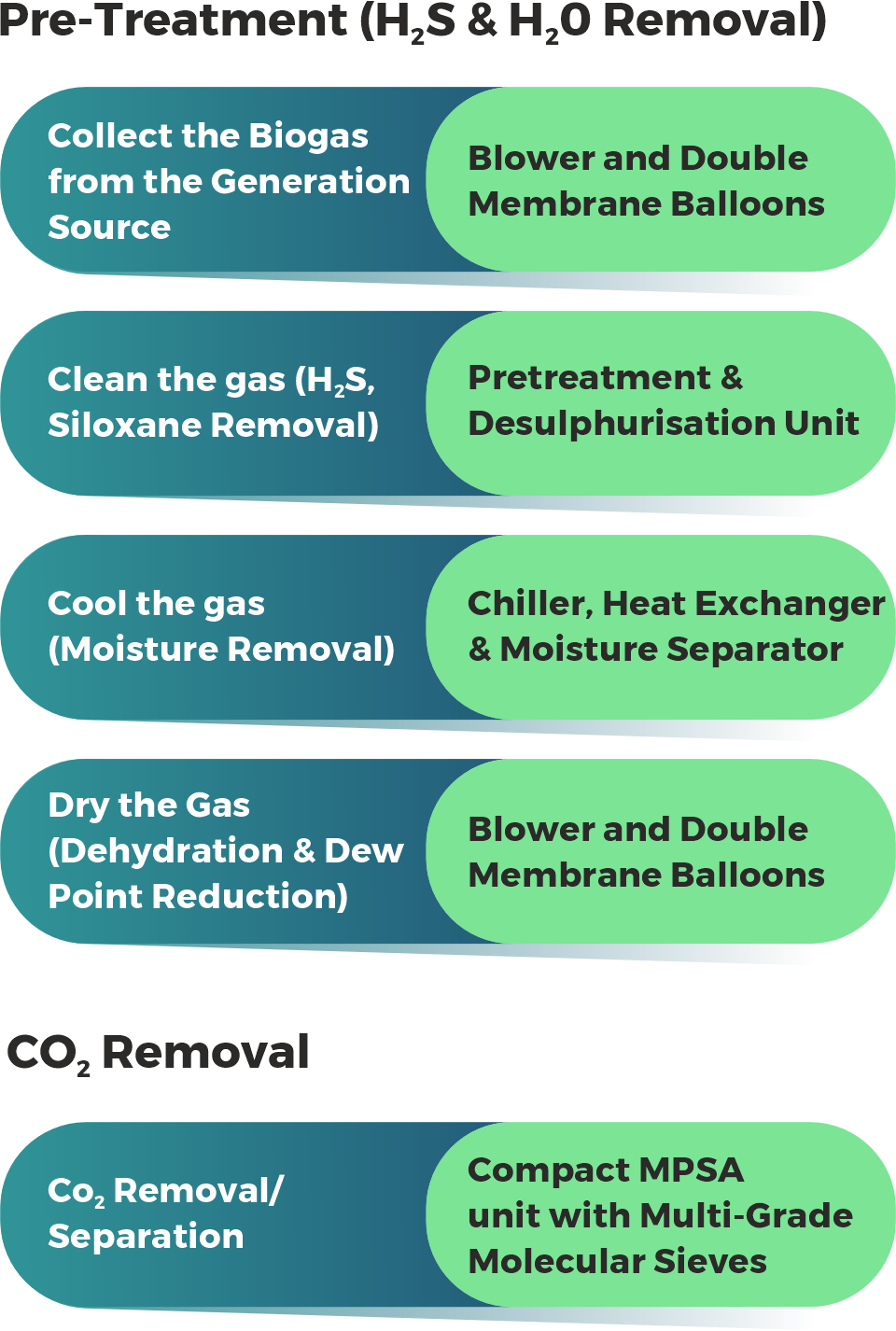

Purification area: The gas holder is an airproof container aimed to collect various gases during the fermentation process. Provided a gas outlet which enables biogas to come out of the digester to get purified to CBG via a gas purification system (PSA).

Filling Area: The final good in the form of gas will now shift to the filling area. Here, the compressed biogas will be filled into cascades. These are the cylinders into which, gaseous are secured and ready to be sent to pumps.

Bio Fertilizer Area: As the final good is prepared, the waste produced by the plant transforms into two different elements, slurry (Liquid fertilizer) and Organic manure (Solid fertilizer). Our organization also looks for slurry and organic manure as these two are highly beneficial for farming. Hence, we buy back all the final goods produced by the plant.

Nexgen CBG Manufacturing Project

There are a number of environmental and sustainable development benefits associated with the CBG manufacturing plants.

- Bio-slurry has important benefits. These include:

- replace expensive chemical fertilisers, reducing the production cost of small farmers;

- improve soil fertility, increase productivity and reduce vulnerability to droughts and climate hazards;

- facilitate growing vegetables nearby the house, improving diets (food nutrition)

- Biogas (CBG) has multiple benefits. These include:

- Reduction of natural gas import,

- Reduction of GHG emissions,

- Reduction in the burning of agriculture residues,

- Remunerative income to farmers,

- Employment generation & Entrepreneurship,

- Effective waste management

- Delivers a high-quality product with a product guarantee and after-sales services

- Helps in getting subsidy money and loans to facilitate the investment.

- Modular design

- Operator-oriented implementation

- Prefabricated and -tested construction

- Fully integrated systems

- Service and maintenance

- 24/7 hotline for error analysis and troubleshooting

Why you must establish a Compressed Biogas Plant ?

Green clean energy is one of the fastest-growing industries worldwide. The global renewable energy market is anticipated to drive growth at a CAGR of 8.6% from 2023 to 2030. Additionally, in the current scenario, green energy is one of the most secure industries to dive into. The government has already initiated multiple schemes to support this industry. It is both environment and pocket friendly from the investor's perspective.

Let’s have a core understanding of the benefits that come with the CBG Manufacturing Plant.

- Lifetime business for the generation

- Lifetime return on sales

- Increasing demand for renewable energy

- Low risk with consistent earning and business growth

- 100% Production Buyback

- World-class training for seamless operations

- Collateral-free loan assistance up to Rs. 2 Crore

- State Art Plant & Machinery with a robust supply chain

- Income tax holiday for five years

- GST benefit on Compressed Biogas Manufacturing Plant

- Subsidised rate of interest on the loan

- Waiver on land Conversion charges

- Waste to energy program (Ministry of New and Renewable energy) The objective is to promote the setting up of projects for the recovery of energy in the form of Biogas, Municipal solid waste, and Biomass gasifiers.

- National Policy of Biofuels (Ministry of Petroleum and Natural Gas)

The policy has been made to build the Biofuels market in India which has a strategic significance to meet the goal of the ongoing government initiatives like Swachh Bharat Abhiyan and Make in India. - Biogas scheme (Ministry of New and Renewable Energy)

The objective of the scheme is to support Biomass based Cogeneration Projects in Sugar mills and other industries for power generation in the country. (source: MNRE) - SATAT initiative (Ministry of Petroleum and Natural Gas)

The objective of the scheme is to set up CBG plants and produce and supply CBG to encourage entrepreneurs.